How Oxyacetylene Technology Transformed Locomotive Firebox Repairs

In the golden age of steam railroading, when iron horses thundered across America’s expanding rail network, a persistent problem plagued railroad shops from coast to coast. The mighty locomotives that powered the nation’s commerce were being laid up for weeks at a time, not due to major mechanical failures, but because of something as seemingly simple as leaky fireboxes. The solution would come from an innovative New York company and a revolutionary welding process that would forever change the landscape of locomotive maintenance.

The Challenge That Stopped Trains in Their Tracks

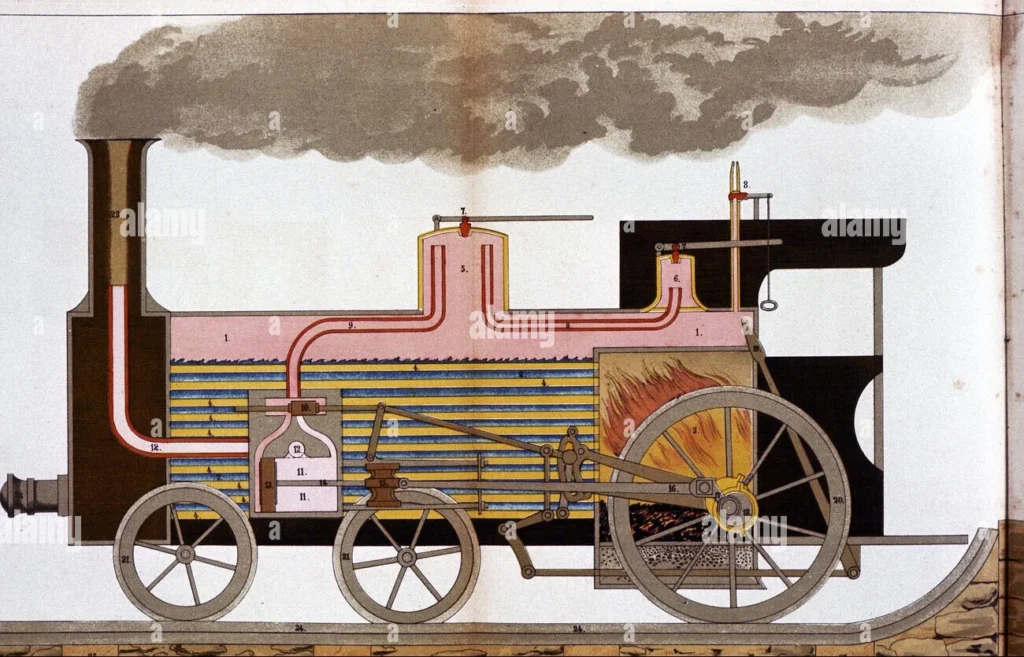

Picture this: It’s 1920, and railroad shops across America are bustling with activity. Steam locomotives, these mechanical marvels weighing hundreds of tons, arrive daily with a vexing problem that threatened the very foundation of rail transportation. Their fireboxes—the beating heart of the steam-generating system where coal burned at temperatures exceeding 2,000 degrees Fahrenheit—were developing leaks at their riveted joints.

The firebox was truly the soul of every steam locomotive. Enclosed within the boiler’s water jacket on five sides, this rectangular steel chamber endured extreme thermal stress as it expanded and contracted with each heating and cooling cycle1. The constant bombardment of heat, combined with tremendous pressure differentials between the fire side and water side, created an environment that pushed materials to their absolute limits.

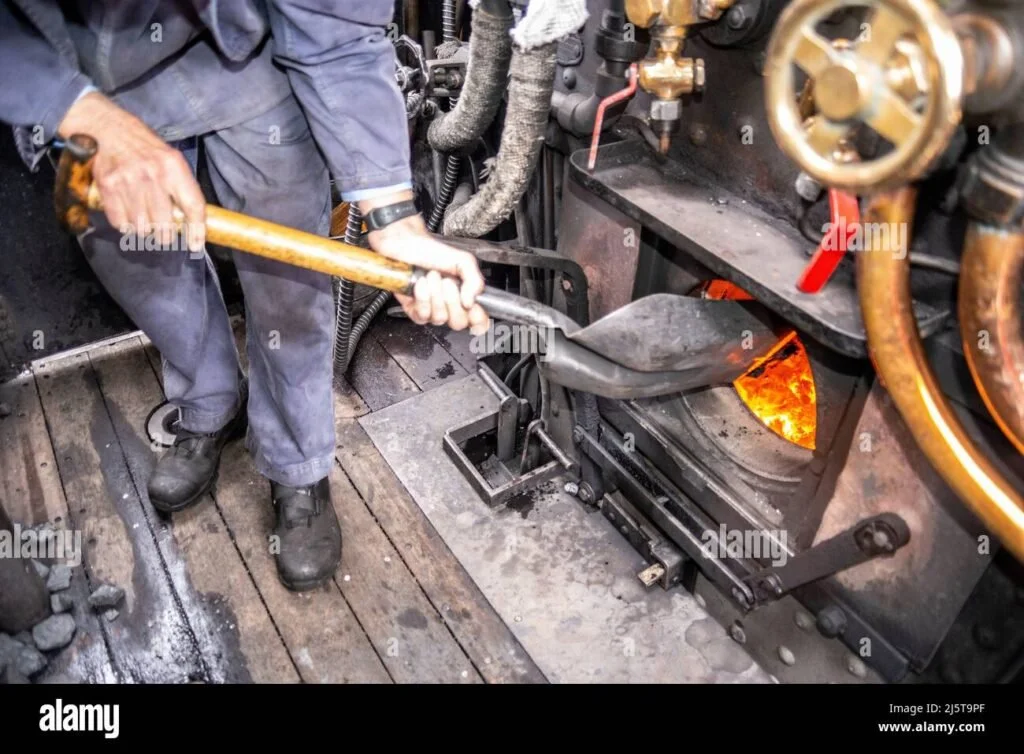

A fireman shovels coal into a locomotive’s firebox

Every time a locomotive fired up, the firebox walls would expand dramatically. When it cooled down, they would contract with equal force. This endless cycle of thermal expansion and contraction placed enormous stress on the riveted joints that held the firebox together. Inevitably, these joints would begin to weep steam and water, rendering the locomotive unsafe for operation until repairs could be completed.

The traditional repair method was both time-consuming and catastrophically expensive1. Shop crews would have to remove hundreds of rivets, cut out damaged sections, fabricate new pieces, and reassemble everything with thousands of new rivets. A typical firebox repair could keep a locomotive out of service for three to four weeks—an eternity for railroad companies that depended on every available engine to move freight and passengers.

Locomotive undergoing repairs in a railroad shop, circa 1920s

Enter the Air Reduction Company

The solution to this widespread crisis came from an unexpected source: the Air Reduction Company of New York, founded in 1905 by Walter W. Birge. Initially focused on separating atmospheric gases for industrial use, the company had pioneered the commercial application of oxyacetylene welding and cutting by 1903. By the late 1910s, they had developed what they called the “Airco Process”—a sophisticated oxyacetylene welding technique that could create stronger, more durable joints than traditional riveting.

The Airco Process was based on a deceptively simple yet revolutionary principle: combining pure oxygen with acetylene gas to create an intensely hot flame capable of reaching temperatures up to 6,000 degrees Fahrenheit. This flame could melt steel cleanly and precisely, allowing skilled welders to fuse metal pieces together at the molecular level. Unlike riveted joints, which relied on mechanical compression, welded joints became a continuous piece of metal with superior strength and flexibility.

What made the Airco Process particularly revolutionary was not just the equipment, but the systematic methodology the company developed for locomotive firebox repairs. Working with experts like George L. Walker and R. T. Peabody from their Engineering Service Department, Air Reduction Company created detailed procedures that turned what had been an art into a precise science.

Vintage Airco oxyacetylene welding torch

The Science Behind the Revolutionary Solution

The Airco welding process for locomotive fireboxes was far more sophisticated than simply applying a torch to metal. Every aspect was carefully engineered to account for the unique stresses and requirements of firebox construction under extreme operating conditions. The foundation of successful firebox welding lies in understanding thermal expansion and metal behaviour under the punishing environment of steam locomotive operation.

When welding firebox sheets, Airco technicians would begin by creating precise 45-degree bevelled edges along the joints to be welded, leaving a critical 3/16-inch gap at the bottom of the vee-shaped joint. This gap wasn’t an oversight—it was a meticulously calculated design feature that allowed for thermal expansion and ensured complete penetration of the weld metal. The welding sequence was equally important and counterintuitive.

Rather than welding continuously around a joint, Airco welders employed a sophisticated “tack and back-weld” technique1. They would begin by welding about one inch of joint, then move 10 inches away and weld back toward the starting point. This seemingly backward approach prevented unequal thermal expansion that could warp the firebox sheets or create internal stresses that would lead to catastrophic future failures1.

Heavy-duty oxygen acetylene cutting and welding torch

Full-Welded Fireboxes: The Pinnacle of Innovation

For full-welded fireboxes—those with all joints welded instead of riveted—the process became extraordinarily complex1. The firebox would be mounted on its mudring (the foundation casting that supported the entire firebox assembly) and bolted securely in place. Each joint required meticulous preparation, with both edges bevelled to create the optimal welding groove.

The welding equipment itself was precisely calibrated for maximum effectiveness. Airco welders used No. 8 tips in their welding torches for most firebox work, with 3/16-inch or 1/4-inch welding rod depending on the specific application. The flame adjustment was absolutely critical—too hot and the metal would burn through, too cool and proper fusion wouldn’t occur. Experienced Airco welders could judge flame temperature and characteristics by sight and sound, adjusting their technique based on the colour and behaviour of the molten metal.

Revolutionary Techniques for Every Challenge

The Air Reduction Company developed specialised techniques for virtually every type of firebox repair scenario that railroad shops encountered throughout the steam era. These innovations represented a complete reimagining of locomotive maintenance practices.

Semi-Welded Fireboxes: A Strategic Compromise

Semi-welded fireboxes offered a brilliant compromise solution for shops that wanted to gain the benefits of welding in critical areas while maintaining some riveted construction. Typically, the lower vertical joints where thermal stress was highest would be welded, while upper sections remained riveted. This approach was particularly popular because it eliminated leaks in the fire zone—the area of highest heat and stress—while requiring less extensive shop modifications.

Inside a railroad shop during the early 20th century

Patch Work: Triangular Innovation

Patch work represented perhaps the most innovative aspect of the entire Airco Process1. Traditional firebox patches were rectangular, but Airco engineers discovered through extensive testing that triangular patches were far superior. The reason was elegant in its engineering simplicity: triangular patches had sides that didn’t run parallel to staybolt hole patterns, avoiding the stress concentration that consistently weakened rectangular patches1.

The welding sequence for patches was carefully choreographed to manage thermal stress with scientific precision. For a triangular patch, welders would begin at one corner, weld approximately 10 inches, then let the joint cool completely before proceeding to the next section. Strategic preheating of adjacent areas allowed for controlled thermal expansion and prevented the formation of dangerous stress cracks.

Crack Repair: The Ultimate Test of Skill

Crack repair required the most skill and experience of any Airco technique. Cracks between staybolt holes were particularly challenging because the surrounding holes had to be filled with precisely fitted steel discs. Each disc would be bevelled around its edges and tack-welded in place before the crack itself was welded. The entire area had to be kept at red heat during the process to ensure uniform thermal expansion and prevent the introduction of new stresses that could cause future failures.

Inside a locomotive repair shop, circa 1920s.

The Human Element: Masters of Fire and Steel

Behind every successful Airco welding operation were highly skilled craftsmen who had mastered both the art and science of oxyacetylene welding. These weren’t simply workers following instructions—they were artists whose medium was molten steel and whose canvas was the firebox of a steam locomotive. A master Airco welder needed to understand metallurgy, thermal dynamics, and mechanical engineering at an expert level.

They had to be able to judge metal temperature by colour with perfect accuracy, adjust flame characteristics by sound alone, and manipulate molten metal with precision measured in fractions of inches. The best welders could sense when a joint was building up internal stress and adjust their technique accordingly to prevent future failures1. The work was physically demanding and often dangerous by modern standards.

Welders worked in cramped spaces inside fireboxes, surrounded by hot metal and exposed to intense heat and brilliant light1. They wore minimal protective equipment by today’s standards—typically just dark glasses and leather aprons. Despite these challenging conditions, the best Airco welders took enormous pride in their craft and the locomotives they restored to service.

The Economics of Revolutionary Innovation

The financial impact of the Airco Process was nothing short of dramatic for the railroad industry. Where traditional firebox repairs might cost $3,000-$5,000 in materials and labour while keeping a locomotive out of service for a month, Airco welding could often complete the same repair for $1,500-$2,000 in just one week. For major railroads operating hundreds of locomotives, these savings amounted to millions of dollars annually.

But the economic benefits extended far beyond immediate repair costs. Airco-welded fireboxes typically lasted 50-100% longer than their riveted counterparts1. The welded joints were more flexible and better able to handle thermal cycling, while their steam-tight integrity remained superior throughout their entire service life1. This meant fewer breakdowns, less unscheduled maintenance, and higher locomotive availability—the holy grail of railroad operations.

Railroad maintenance superintendents quickly became believers in the revolutionary Airco Process. The Pennsylvania Railroad, one of the most conservative and technically demanding operators in the country, became one of the largest adopters of Airco welding techniques. Other major carriers, including the New York Central, Santa Fe, and Southern Pacific, soon followed suit, revolutionising their maintenance practices25.

Beyond Fireboxes: The Broader Industrial Impact

While locomotive firebox welding was perhaps the most visible application of the Airco Process, its impact extended throughout railroad maintenance operations and beyond. The same techniques that worked so brilliantly on fireboxes proved equally effective for repairing boiler drums, superheater elements, ash pans, and numerous other locomotive components.

The Airco Process also found critical applications in railroad infrastructure. Bridge repairs, rail welding, and maintenance shop equipment all benefited from oxyacetylene welding techniques. The flexibility and portability of Airco equipment made it ideal for field repairs, allowing maintenance crews to fix problems on-site rather than towing disabled equipment back to major shops.

Perhaps most importantly, the success of the Airco Process helped establish welding as a legitimate alternative to riveting and bolting across the entire industrial landscape. The techniques pioneered in locomotive shops found their way into shipbuilding, construction, and manufacturing, contributing to the broader industrial transformation of the early 20th century.

The Sunset of Steam and Legacy of Innovation

As diesel locomotives began replacing steam power in the 1940s and 1950s, the demand for firebox welding naturally declined. The last great era of Airco firebox welding came during World War II, when railroads pushed their steam fleets to the breaking point moving troops and war materials. Skilled Airco welders worked around the clock to keep aging locomotives in service, their expertise more valuable than ever.

Yet even as steam locomotives faded into history, the techniques and principles developed for firebox welding lived on. Modern arc welding, MIG welding, and TIG welding all trace their lineage back to the pioneering oxyacetylene work of the early 20th century. The systematic approach to weld preparation, sequencing, and thermal management developed by the Air Reduction Company became standard practice across the welding industry.

Today, preserved steam locomotives around the world still benefit from Airco-style welding techniques. Heritage railways and museum shops use updated versions of these methods to restore and maintain historic locomotives, keeping alive both the machines and the craftsmanship that defined an era.

Conclusion: Fire, Steel, and Enduring Innovation

The story of Airco welding of locomotive fireboxes is ultimately a story about human ingenuity applied to solve critical practical problems. In an age when steam locomotives were the lifeline of commerce and transportation, the Air Reduction Company developed techniques that kept these magnificent machines running reliably and economically.

The Airco Process represented more than just a welding technique—it was a systematic approach to solving complex engineering challenges through careful observation, scientific method, and skilled craftsmanship. The welders who mastered these techniques were artists as much as they were technicians, creating joints that were stronger, more durable, and more reliable than anything that had come before.

As we look back on this remarkable chapter in industrial history, we can appreciate both the technical innovation and the human dedication that made it possible. The legacy of Airco welding extends far beyond the railroad shops where it was perfected, influencing generations of welders and engineers who continue to push the boundaries of what’s possible when fire meets steel.

In the end, the story of Airco welding of locomotive fireboxes reminds us that progress often comes from applying new technologies to solve old problems, and that the combination of scientific understanding and skilled craftsmanship can achieve results that seem almost magical to those who witness them. The locomotives may be silent now, but the techniques that kept them running continue to shape our world in ways both seen and unseen.